ZBE: Zero Bio Emissioni

Project Description

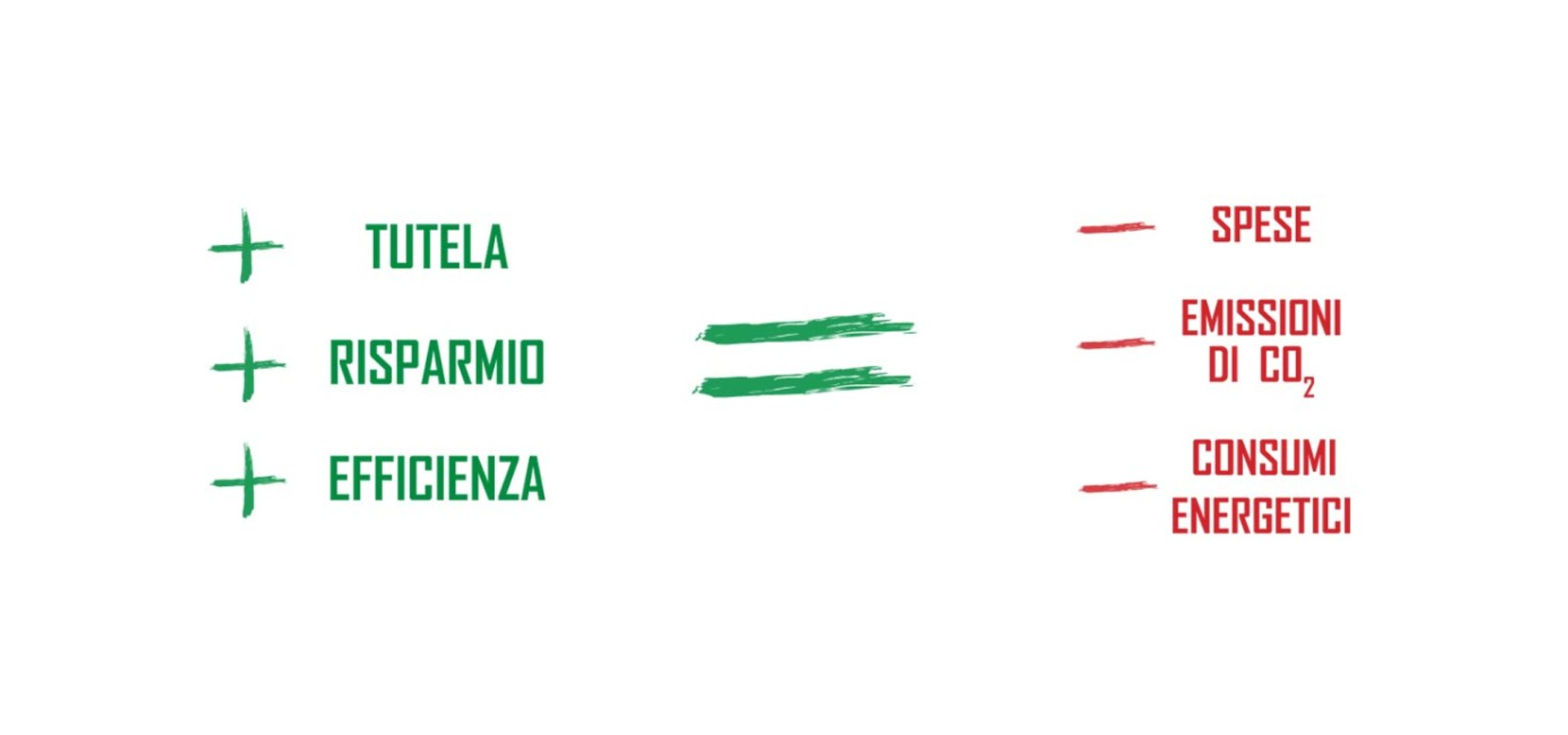

This project of R&S can facilitate low carbon production, have an energetic saving and the ensuring processes, recycling, depollution and use of high value materials from residues and reconstruction.

This project aims to make on the market four new products:

- “NEWLIFE”: a mixture of animal fat and vegetable oil able to ensure the life time of any biofiltering material, maintaining biological and depurating features. This will be administrated nebulized over the biofiltering materials of any biofilter.

- “BIOFIL”: optimized of the containment of atmospheric emissions below the parameters set out in table Annex 5 of D.M. 6/7/2012. This material presents features to be compliant with the dejection system at the next point. The biofiltering material is optimized for specific emission ranges with features listed in Annex X d.lgs 152/2006.

- “BIOSCRUBBER”: system able to treat the gaseous emissions with low management costs and high dejection efficiency. It will present new features thanks the presence of a ultrasonic cavitator and the use, in the septum, where the flux of smokes will be treated with upstream water, of biofiltering materials of biological matrix (this is an innovation compared the actual scrubbers in which there are plastic bodies). Bio scrubber will be composed by systems to monitor and maintain active biological processes of microorganisms, typical of biofiltration and atmospheric depollution. Therefore, it has an extremely innovative technology that it’s able to verify biological markers. Until microorganisms will be alive with the treatment of smokes to purify, it will mean emissions will be compatible with the reference environment. In addition, it possesses self-protection systems of the bacterial charge constituted by an ultrasonic cavitator, for the sterilization, suitable to make the waste of flow output, the recirculating liquid saturated perfectly compatible with the fertilizers of which To D. LGs. 75/2010.

- “IDROTERRA”: after tests on reactor input vectors the optimal recipe will be produced for the direct production of the wanted liquid fertilizer underlying the characteristics to the characteristics of D. LGs. 75/2010. This fertilizer will be ideal for agricultural crops and to produce high-intensity biomasses.

In this way, it will delete problem of exhausted wastewater discharges as these are automatically processed into a product that is sold after the usual quality control analyses of the batches collected.

The use of these new products will give a better competitiveness, better efficient technologies and with low emission of carbon in industrial processes. At the end, the exhausted material can be used as Windrow for farmland without going to create other waste.

Project Details

Project ZERO BIO-EMISSIONI

Program DM 1 GIUGNO 2016 “Horizon 2020– PON014/2020”

Ranking Horizon 2020 PON

Field Research & Innovation

Zero Bio Emissioni

ZBE project, designed for the measure “HORIZON 2020- PON 2014/2020” – Technologies related to materials for a sustainable industry, able to facilitate low-carbon production, energy saving, as well as process intensification, recycling, de-pollution and the use of high value-added materials from residues and construction.